For carbonated and still products: Filling with and without pressure

Range of applications

- Still and carbonated high and low-acid products

- Products with

- Particles up to 3 x 3 x 3 millimetres

- Fibres up to 2 x 10 mm

Technical features

- Method of filling

- For still products: Non-contact in full jet

- For carbonated products pressed-on, according to counter-pressure principle

- Inductive flow meter for determining the quantity of liquid

- Two different filling speeds

- Product feed from above via a sliding ring manifold

- Sterilisation with steam

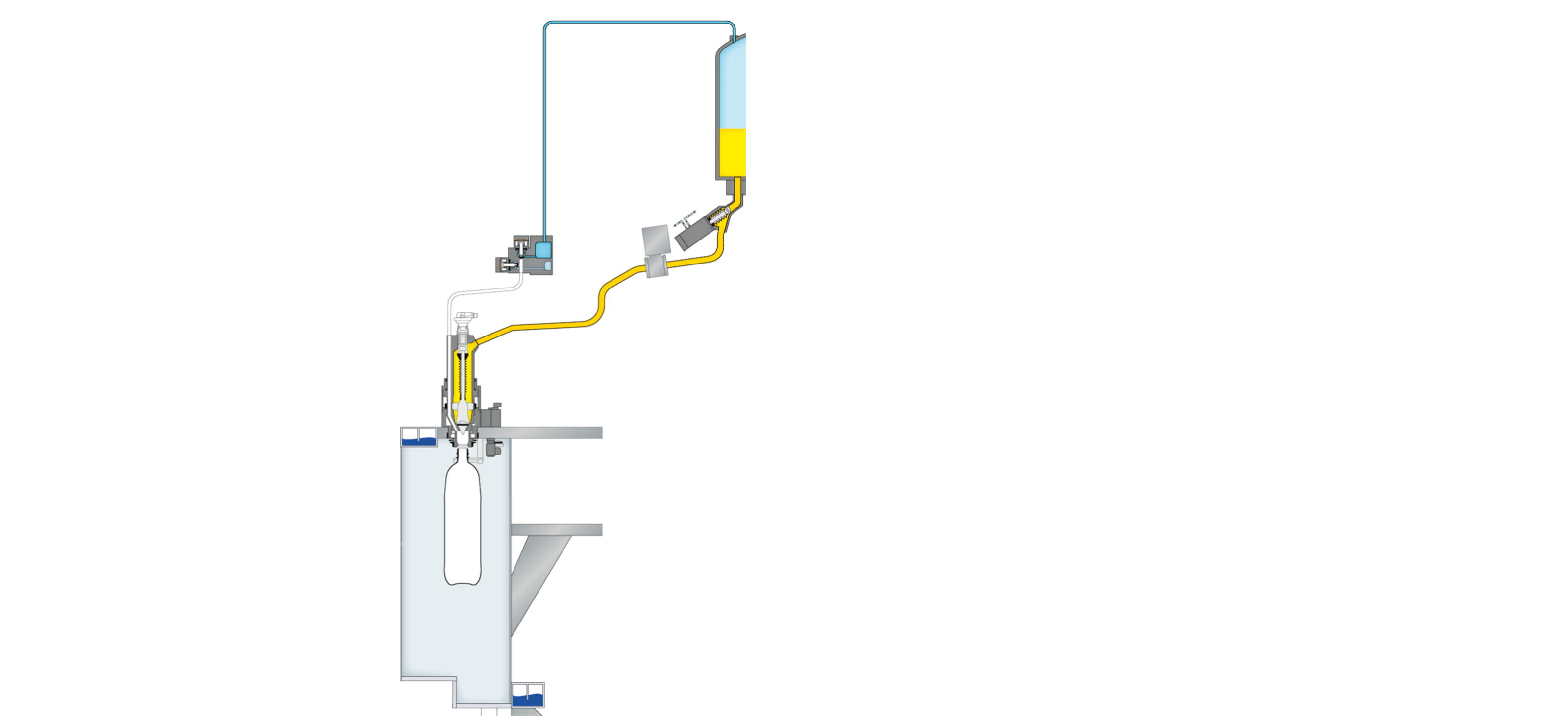

VFJ: Volumetric filling, Flow meter, full Jet

Filling valve

Product discharge valve

Aseptic area

SIP cup

Hydraulic seal “Liquid seal system”

Pressing-on unit

Valve stem

Pneumatic cylinder, valve stem

Snifting and CIP valve

Pressurisation valve, return gas valve and CIP valve

Snifting and CIP return channel

Pressurisation channel and CIP return channel

Inductive flow meter

Switching valve fast/slow

Central bowl

Benefits to you

- Flexible use for different products

- High microbiological safety

- Foam-inhibited filling process

- Precise fill quantities

- Optimum flow behaviour

- Minimum product loss

- Quick and media-efficient disinfection

- No CIP distributor needed