Spotlighting Krones’ entire portfolio

At drinktec 2025 in Munich, it was all about beverages and liquid food. And we at Krones presented a variety of innovations and upgrades, right in line with our motto “Solutions beyond tomorrow”.

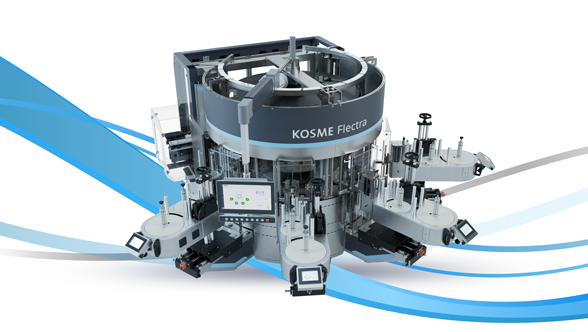

On an exhibit space of around 10,000 square metres, we showcased the Krones Group’s entire portfolio: From superior process technologies to energy- and media-efficient filling and packaging solutions right through to fully automated intralogistics concepts – Krones demonstrated how digital transformation, sustainability and efficiency are not only compatible but, in fact, enhance each other.

The future has a name

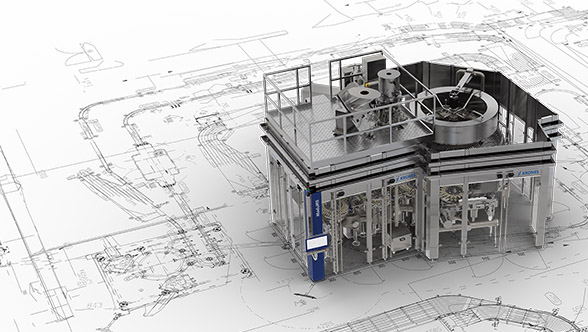

At this year’s drinktec, Krones presented for the first time a data-based, fully automated line system for filling non-carbonated water into PET containers. It’s the line of the future, and we call it Ingeniq.

It was designed as the answer to the most frequent questions (or rather requests) we’ve got from customers recently. And it translates what Krones presented as a vision at drinktec 2022 into shopfloor reality: a line that couples low total cost of ownership with consistently high efficiency.

The system consists of modular and standardised components that leverage robotics and artificial intelligence in a well-thought-out design that reduces the overall complexity of the line layout.

We’ll also focus on these topics

Savings in sight

Energy and packaging material – without a doubt, these two areas offer the greatest potential for savings on a PET line .

At drinktec, Krones showcased individual solutions that demonstrate how deliberate, well-thought-out measures can yield valuable gains and savings in your ongoing production operations.

Minding your footprint in more ways than one

For many beverage makers, the decision to invest in a new line is driven by a need for a small physical footprint and therefore a compact layout. But space requirements are just one of many aspects informing our efforts to develop new and improved solutions for glass containers.

Full speed ahead into the future

The can is a popular and sustainable packaging option. For beverage producers who use cans, Krones offers turnkey lines from a single source – right through to the high-output range.

At drinktec, we exhibited many machines and features that will not only take your production speed to the next level but also make you a leader in terms of sustainability and digital innovation.

It doesn’t get any safer than this

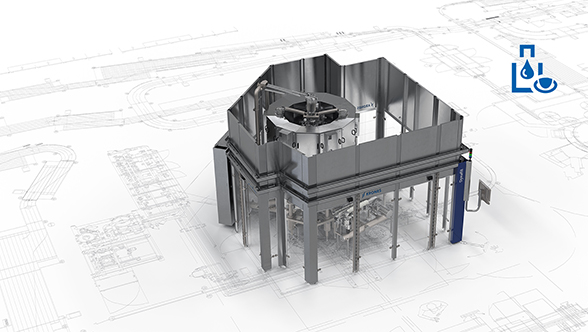

If you want to ensure a microbiologically safe environment for sensitive drinks, there’s no way round aseptic filling. So it’s hardly surprising that the technology is booming right now. Our developers are also huge fans – which is why they’re continually finding new ways to make our systems even better. First and foremost, they’ve focused on shrinking the physical footprint, reducing resource consumption, shortening cleaning times and speeding up product change-overs.

The Krones family advantage

We take a holistic view of things. And so, when it comes to product manufacture, we support our customers throughout the entire process, from the raw materials right through to the finished product.

To ensure that our efforts are successful, we rely on the vast expertise of the entire Krones family, leveraging synergies and know-how across the group. At drinktec, we showcased an integrated, resource-saving process technology portfolio in collaboration with our subsidiaries Steinecker, Milkron, HST, Evoguard, Ampco Pumps, Perfinox and GHS.

Absolute efficiency is key

Short pathways, lean processes and agile material flows that can be adapted to current production and shipping needs with utmost flexibility – when it comes to intralogistics, absolute efficiency is key. In order to achieve it, we leave nothing to chance in the planning and execution of intralogistics projects.

The requisite expertise here comes from System Logistics. With storage and retrieval, order-picking and driverless transport systems as well as the matching software solutions, System Logistics is your ideal partner for implementing integrated intralogistics solutions.

PET Point: packed full of know-how

If you visited drinktec and walked from the Krones stand in Hall B6 into Hall C6, you’ll have arrived once again at Krones. Or rather, you’ll have found three Krones subsidiaries specialising in plastics beyond filling and packaging.

Netstal, MHT and Krones Recycling teamed up as a single point of contact at the drinktec PET Point for all those seeking solutions that close the plastics loop and even reinvent it.

Savings that count

Where can I save energy and other resources in my production operations? How can I prevent waste and achieve circularity? Which sustainability goals are realistic – and what do I need in order to achieve them? These days, companies can’t afford to ignore questions like these. Which is why we are designing innovations that reconcile sustainability and profitability.

Whether it’s our enviro-certified technologies, digital services for optimising production and resource use or our comprehensive energy and sustainability consulting, we’ve got solutions that will sustainably transform our industry.

Next-level production

Krones and digital transformation are a perfect match. Krones has long been much more than a traditional machinery manufacturer. As a technology company serving the beverage and liquid food industry, we help our customers implement digital solutions that enable them to achieve lasting success despite increasing complexity and fast-paced change. We can do that thanks to our broad portfolio, which is already tailored to the industry, offering a diverse range of promising software solutions that help bring clarity to complex production processes, optimise them and take them to the next level of efficiency and sustainability.

Top performance together

As the name suggests: The experts of the Krones Lifecycle Service are real partners and always stay by your side for the entire service life of your Krones equipment – worldwide and around the clock. This includes a comprehensive after-sales support, but also extends far beyond that: We support you in optimising the performance and service life of your plant, organising your warehouse in the best possible way and always keeping an eye on resource-saving options for your production. How do we do that? By combining our many years of know-how, high-quality products and intelligent, digital services. We identify your requirements and wishes and translate them into solutions tailored precisely to your needs – from individual services to practical, modularly configurable service packages.

We also unveiled a number of service innovations at the drinktec, such as proactive support enabled by downtime- and line-performance-monitoring or the use of AI for optimised production planning.

44 sessions to rewatch as often as you like

Over the course of the entire week of drinktec, our Forum hosted a variety of speakers from our own team, our customers and other partners. More than 40 short presentations outlined the latest technological trends, provided exclusive insights into production practices and discussed key topics for the future of our industry. Did you miss some or all of the presentations? Not to worry! Next to each title in the agenda, you’ll find a link to the recording of the live session.

Topic of the day: The line of the future

At the last drinktec, it was still just a vision. Now, it’s reality. Find out what the PET line of the future is all about – and experience a fantastic full-circle moment with us.

Let's start into the future: a warm welcome from the Krones Executive Board

Lines of the future: the seamless fusion of machines, software and services

Rethinking service: shared responsibility, amplified success

Engineering excellence: unveiling the PET line of the future

The future is now: panel talk with Niagara Bottling and Shepley Spring

A new way of operation: working with the PET line of the future

Autonomous material handling: taking automation to a new level

Topic of the day: Digital transformation

Tailor your transformation to your needs. Find out how you can use digital services, automation solutions and AI applications to take your production to the next level – with practical explanations and real examples from our industry.

Facing automation and digitalization challenges in the beverage industry

Krones.world: your central access to all digital services

Everything on one platform: digital services of the line of the future

The use of AI in the beverage industry

A new way of operation: working with the line of the future

Krones as SAP partner: success stories from the industry

OEE improvement via joint collaboration @innocent

Managing complexity across countries: a customer case in Asia and MEA

Reducing maintenance costs through condition-based monitoring @Coca-Cola Europacific Partners

Next level service models: creating exceptional customer experiences

Topic of the day: Sustainability

Dive into the many facets of sustainability – from reducing consumption to leveraging circularity and protecting the climate. Our speakers will give you exciting insights that extend beyond our own industry.

Sustainability at Krones

Krones Recycling: sustainability and economic efficiency

Climate action and circular economy at Krones

Sustainable maintenance with Krones Lifecycle Service

Energy and sustainability consulting: best practice examples

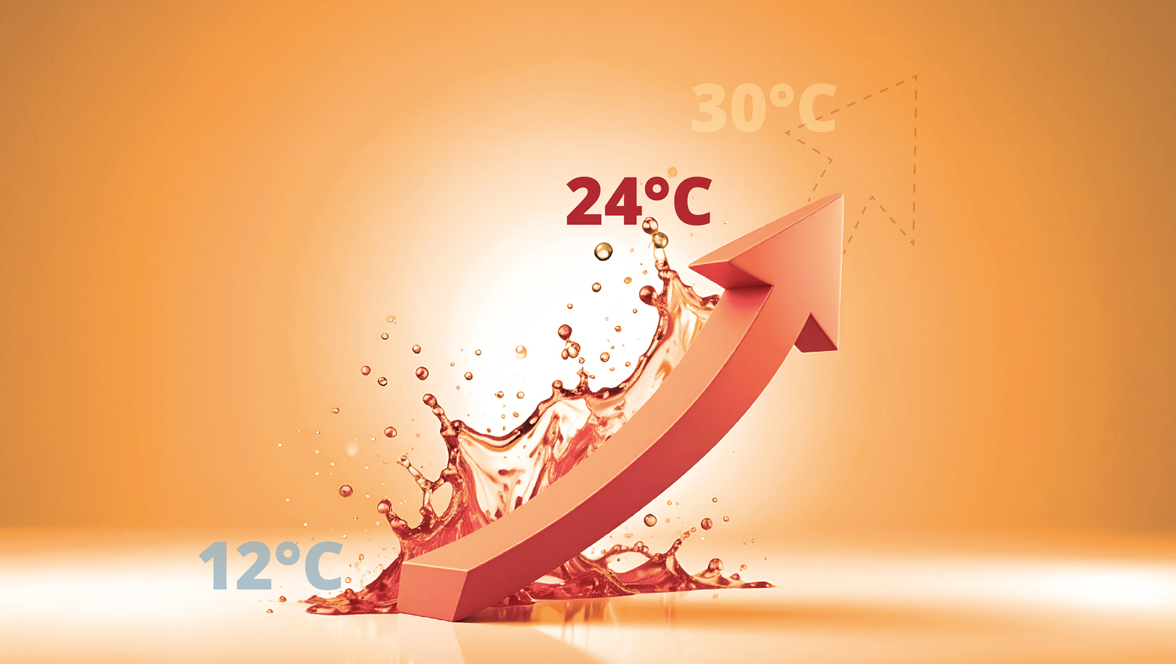

Electrification of tunnel pasteurizers - how heat pumps play a vital role

Sustainable innovations: What can the beverage industry learn from other industries?

Sustainable packaging solutions: LitePac Top

Ambitions put into practice: Asahi's sustainability goals – and expectations of its suppliers

The way to an energy self-sufficient brewery

Feeding the world: alternative proteins and bioprocessing

Making the best of water: efficient treatment and recycling

Topic of the day: Trends and products

From label-less bottles to more efficient beer filling to compact aseptic solutions: What are our development teams working on right now? And which trends are coming to the beverage industry? Find out during today’s forum.

Top trends in packaging

Sustainability meets flexibility: PET solutions for carbonated drinks

Full circularity: closing the loop in PET packaging

Laser decoration: labelless into the future

Top trends in beverages

New solutions for returnables: a technological revolution

Precision meets flexibility: bottle washing with Lavasonic HI

Compact and sustainable: revolutionizing beer filling

A vision takes shape: the can line of the future

Can line challenges, solved: the tunnel pasteurizer as part of the filling block

Aseptic filling: how a cutting-edge technology continues to improve

Smallest possible footprint: a compact-design aseptic block

Topic of the day: Visions

As the fair draws to a close, we’ll look forward instead of back. In fact, we’ll turn our gaze far into the future. The last morning of our forum is dedicated to exploring the challenges of the future – with another very special and exciting talk from one of our customers.

Solutions beyond tomorrow

Getting ready: future challenges in the beverage industry

Leading with AI @Yili: reducing flop rates in food product innovation

Summary and closing