To put it simply, a classic canning line looks like this: Its individual machines – filler, pasteuriser, packer, etc. – are interconnected by means of wide bulk conveyors, on which the cans jostle several lanes deep. Bulk conveyors form the basis for operating the entire line. Most of the time, the containers are spaced out as they travel along the conveyor belt, and at one point or another buffering sections are integrated. In this way, the conveyor serves to ensure an even container distribution if there is a stoppage in the line. Each machine possesses its own control system. Back-up switches at the conveyor emit a signal that informs this control system if the belt leading to the next machine is filling up and the machine must be stopped.

The underlying principle works all right but there is one snag: The requisite equipment has a huge footprint because the wide, rather slow-running bulk conveyors and the buffer sections alone need a lot of space. What is more, the conveyors leading to the single- or double-deck pasteuriser are relatively long which increases the risk of containers falling over.

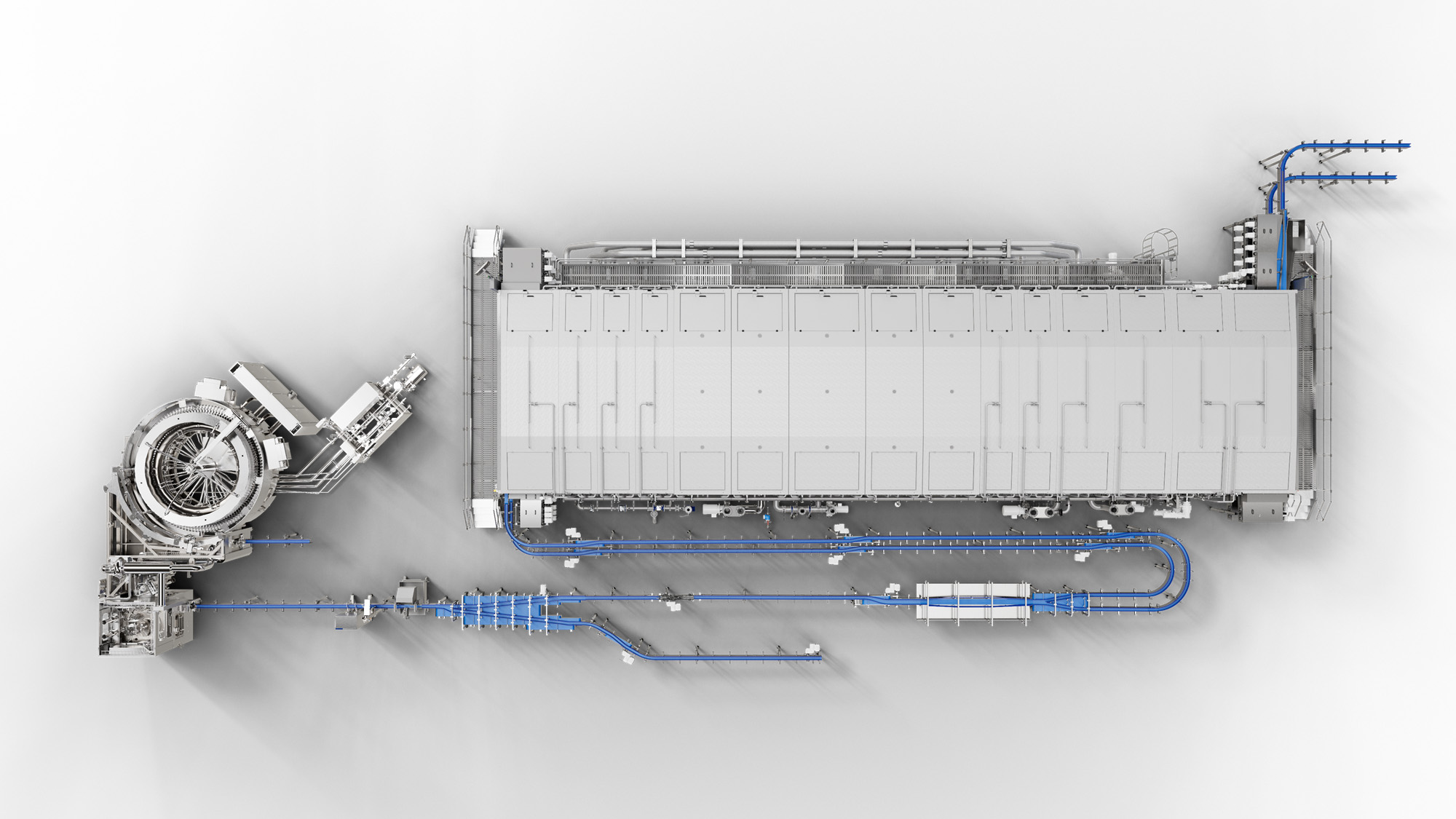

The line layout with the new LinaFlex eSync presents an entirely different picture: The cans race along a narrow, single-lane conveyor in a close-packed flow on a comparatively short bend from the filler to the pasteuriser and from there to the packer. The conveyor does not include a single buffer section. On the contrary: The belts are always completely filled, and the number of cans between the individual machines is kept constant.

Pasteuriser acts as buffer for the entire line

Instead, the buffer for the wet end is hidden inside the tunnel pasteuriser, whose design has been completely reinvented. On each of the decks, a newly developed infeed system ingeniously distributes the cans darting into the machine in single file onto the wide, very-slow-running pasteuriser belt. At the machine’s end, a discharge system guides the cans back onto fast-running single-lane conveyors. The clever bit of this system is located directly upstream: Still inside the LinaFlex eSync machine, a separate variable-speed conveyor that is directly connected to the pasteuriser belt and running faster than the pasteuriser itself creates a free space that can be filled if needed. That provides two buffer sections located one above the other in the double-deck pasteuriser (and one in the single-deck machine) in a minimum of space.